Piano wire, or “music wire”, is a specialized type of wire made for use in piano strings but also in other applications as springs. Piano wire has a very high tensile strength to cope with the heavy demands placed upon piano strings.

Chinese standard: GB4358

American Standard: ASTM A228

Japanese Standard: JIS G3522

Material composition: C(0.7-1.0) Si(0.1-0.3) Mn(0.2-0.7) P(below 0.025) S(below 0.030)

Tensile strength: 1620-3500 MPa depends on wire diameter.

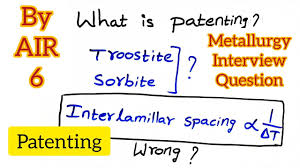

In 1864, Mr. Horsfall in England registered a patent for continuous heat treatment of high-carbon steel wire in his name, which became known as Patenting, which is also called patent heat treatment. In this process, the wire is heated up to 900 degrees Celsius (austenitizing) and then cooled in molten lead to 550 degrees Celsius and remains at this temperature for a short time. Since the sections treated are generally small (e.g. wire rods), so that the resulting structure consists of very fine pearlite preferably with no separation of primary ferrite.

The obtained microstructure has high strength and good ductility, which allows the drawing operation of high-carbon wire.

Due to the toxicity of lead and its environmental hazards, air can also be used for the cooling environment of this heat treatment with some changes.