Suppose you are going to do reverse engineering, that is, for example, you have a piece of unknown steel and you want to manufacture the same. Perhaps the most important step in this route is to know its chemical analysis.

The good news is that this step is easy, it will be send to the laboratory and chemical analysis report is on your desk, but the bad news is that now you have to make decision.

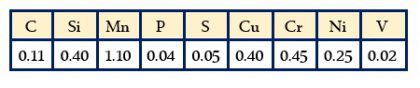

In order to understand the scenario you are facing, consider the laboratory analysis report of a steel product is as this table:

Well… Our way of dealing with carbon, silicon and manganese is clear, but what should be done with 0.40% of copper? May we waive it or should be sensitive about it? If we are going to be sensitive about it, to what extent do we consider it permissible? For example, if 0.30 instead of 0.40 is acceptable or should we accept the cost increase and exactly reach 0.40? Where to draw the borders? What should we do about chromium, nickel and vanadium?

You can see that these are all basic questions and we must find suitable answers for them. But how?

One of the ways to evaluate the importance of that element is considering the application of the part. Certainly, in this direction, having experience is very helpful and beside it we should also refer to references and useful books. This is one of the good books I know in this field:

Alloying: Understanding the Basics, by J.R. Davis, ASM international, 2001

But if we cannot find a specific connection between that particular element and the intended use, or if the use of that part is not clear to us at all, to we reach a dead end.

This is where we have to look for other ways to help us clarify the dark corners of the problem.

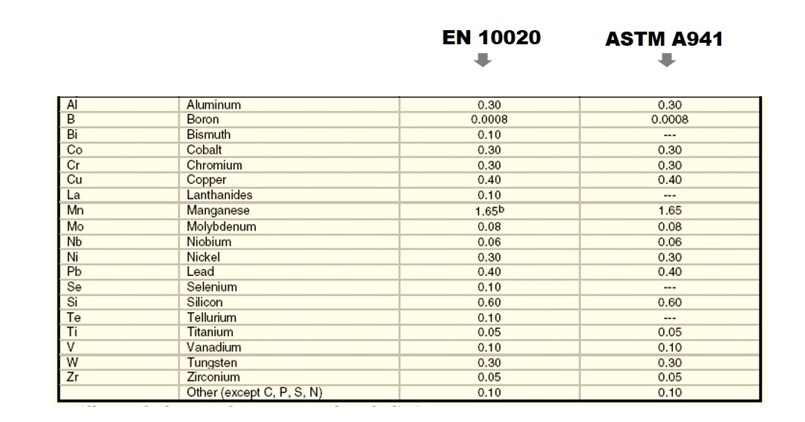

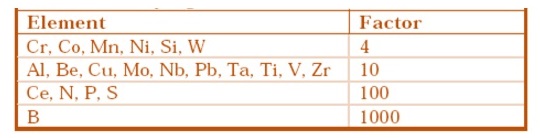

Please see the table below:

This table has specified the approximate boundaries of the importance of elements. In other words, it shows that if in the analysis of steel, the percentage of copper is more than 0.40%, we must consider it as an alloy element.

The same point of view exists in another form and of course with differences in “Key to Steel” book.

In above table, the importance of the elements can be evaluate by reversing the factor of each element. For example, Nickel more than 0.25% will be important.

In the end, it is necessary to mention that each of the above methods should be used along with experience and other references.