What is a failure?

A good definition of a failure is “the inability of a component, machine, or process to function properly.”

Examples of failures are fracture of a shaft or axle and stoppage of the rotating machine; melting of copper wires and interruption in electric supply, etc.

Failure can cause loss of life, unscheduled shutdowns, increased maintenance and repair costs, and damaging litigation disputes.

Many times, a failure analysis incorrectly ends at the identification of the failure mechanism and perhaps causal influences.

The basic objective is to find out the preliminary cause (root cause(s)) of failure.

To prevent future recurrence of the problem it is essential to carry out an investigation aimed at determining the root cause of failure. The results of the investigation can also be used as the basis for insurance claims, for marketing purposes, and to develop new materials or improve the properties of existing ones. The treatment of this subject is therefore important in order to develop preventive measures minimizing the incidence of failure and reducing their associated cost to industry.

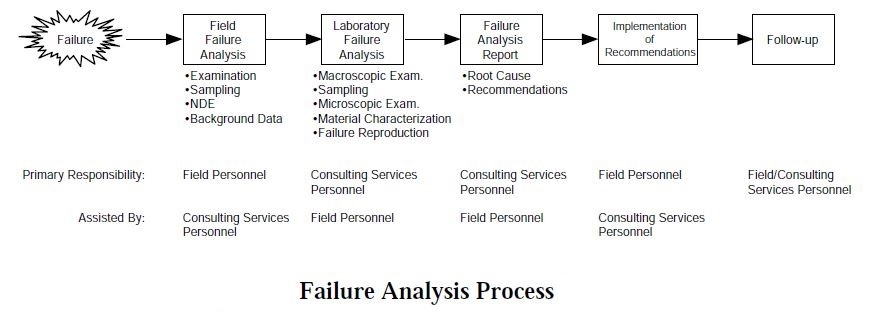

Below figure summarizes the process that is used to collect and organize information on failures so that the information can be used to determine the cause of the failure and prevent the failure from reoccurring.

The Failure Analysis Report is the product of the analyses that are performed by field and laboratory personnel. The recommendations that are provided in the report should be implemented, and a process to follow up on the recommendations should be in place.