MONEL is a group of alloys of nickel (from 52 to 67%) and copper, with small amounts of iron, manganese, and silicon.

It is mainly used for its excellent corrosion resistance and is especially valued for applications in the marine, aerospace and chemical processing industries. There are three widely used MONEL alloys, namely 400, R-405, and K-500.

Unlike steel, nickels are very hard to mine. That’s why MONEL 400 costs six to eight times more than 304 stainless steel. As an expensive alloy, MONEL use is limited to those applications where it cannot be replaced with cheaper alternatives.

MONEL is often traded under the ISO standards 6208 (plate, sheet and strip) 9723 (bars) 9724 (wire) 9725 (forgings) and the DIN 17751 (pipes and tubes). Related ASTM standards are: B127, B164 and B865.

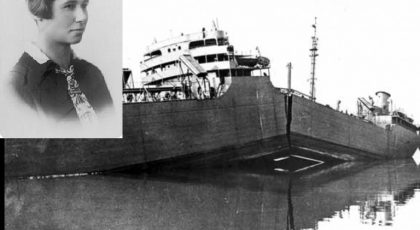

MONEL was named after a metallurgical engineer “Ambrose Monell” (photo above), and patented in 1906. One “L” was dropped, because family names were not allowed as trademarks at that time.